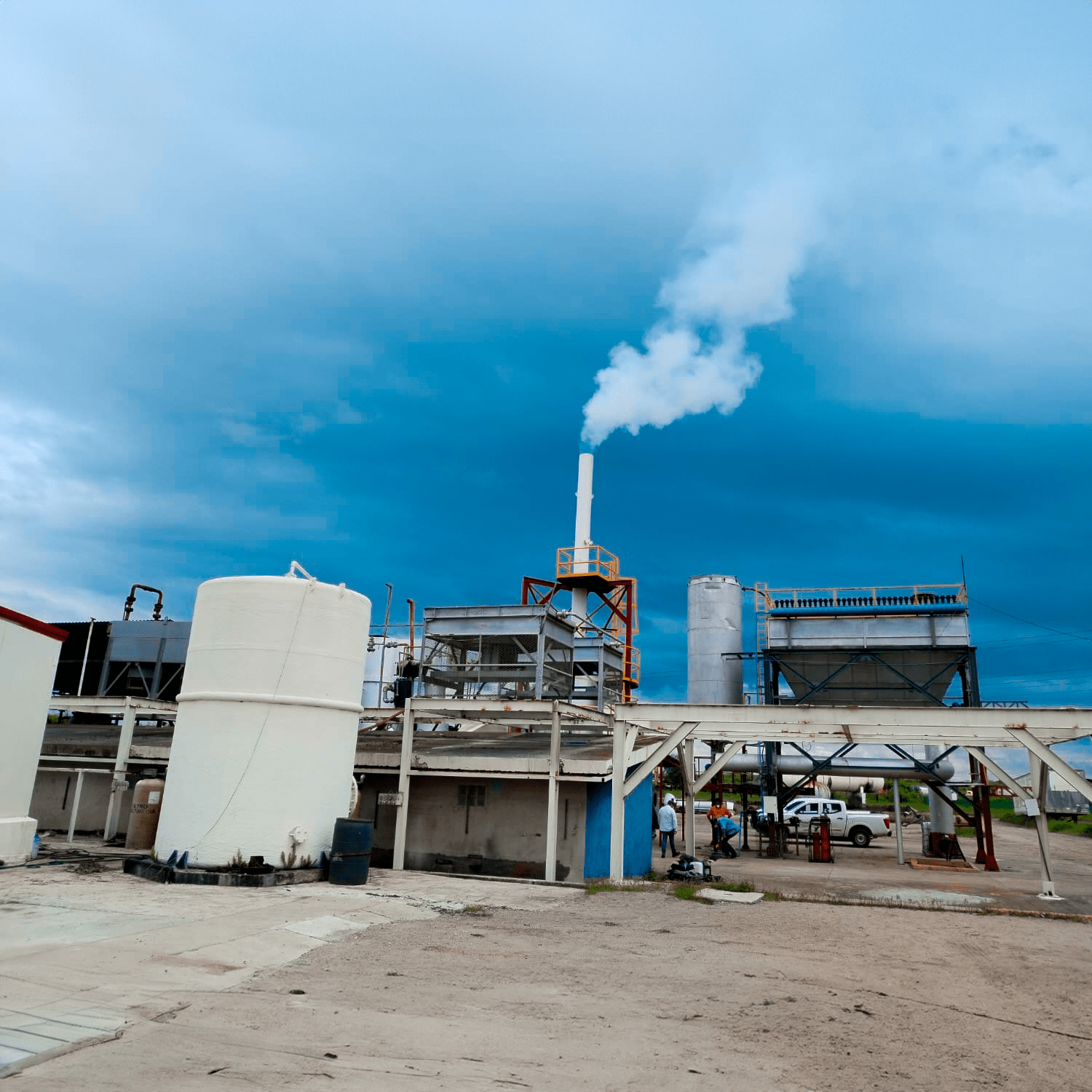

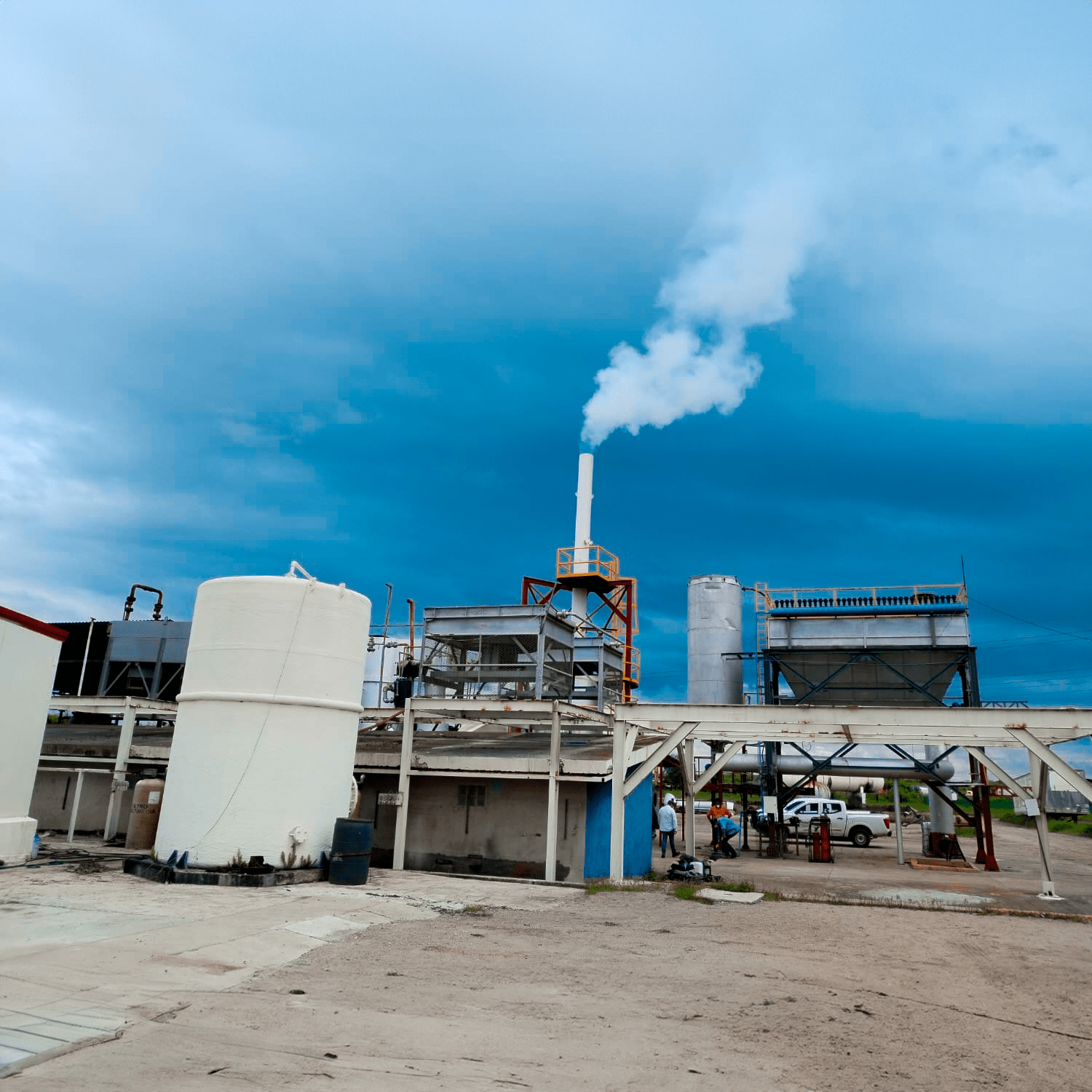

Silver Tailings Roasting Plant.

Coahuila, 2018

COAHUILA 2019

Development of a roasting plant for silver tailings, a state-of-the-art system that has been

created thanks to arduous research, prototype testing, calculations and design,

conceptual and detailed engineering, manufacturing, assembly, automation and control.

This system has become one of the most powerful in the world, allowing us to recover

silver that was previously wasted.

This roasting plant has the capacity to reach temperatures above 1200 degrees Celsius, which is essential to carry out the roasting stage and efficiently separate the silver from the tailings. This high temperature capacity allows us to treat up to 2000 tons of silver tailings per day, exceeding all project expectations.

Thanks to this thermochemical process, we are now able to meet the most demanding standards required by the mining, lime, cement, food, chemical and other industries. This industrial plant allows us to recover silver in an efficient and sustainable manner, providing significant economic benefits to our customers.

In addition, it stands out for its high level of automation and control, which guarantees a safe and efficient operation. Thanks to the conceptual and detailed engineering applied in its design, this system adapts to the specific needs of each client, maximizing the efficiency and optimization of the process.

PLANTA MOVIL 2016

Thermal Desorption is a highly effective technology used to remove harmful organic

compounds from soil. By using high temperatures ranging from 90 to 540 °C, this

innovative technique manages to volatilize and decompose the contaminants present in

the soil. In doing so, they are converted into a gaseous or liquid state, which facilitates their

subsequent disposal in a safe and efficient manner.

This technology has proven to be particularly effective in oil waste remediation, where

organic compounds can be especially persistent and difficult to remove. Thanks to

Thermal Desorption, it is possible to separate volatilizable contaminants from the soil, thus

reducing their negative impact on the environment.

However, it is important to note that the application of Thermal Desorption requires

professional and specialized handling. Since it involves the use of high temperatures, it is

essential to have trained personnel and adequate equipment for its operation.

SANTA MARÍA DAM 2023

The Santa María Dam is a major project whose main objective is to store water for the

irrigation of 25,000 hectares in southern Sinaloa. This work of PRESIDENTIAL

transcendence in the current administration is a challenge that we have joined with

enthusiasm and commitment..

As a company specialized in the design, supply, manufacture, transfer and assembly of piping, we have been selected to carry out the installation of the intake work in a diameter of 4.50 meters, as well as the bottom drainage in a diameter of 3.50 meters. We are proud to be part of this great infrastructure project that will benefit the entire region.

The location of the Santa María Dam in El Rosario, Sinaloa, gives us a unique opportunity to contribute to the development of the area. The irrigation of these 25,000 hectares will allow for the growth of agriculture and the generation of employment in the southern part of the state. In addition, the dam will also provide water for human consumption and hydroelectric power generation.

In this challenge, we have joined forces with the renowned ICA Mexico, the most important construction company in Mexico and Latin America. Together, we are committed to guaranteeing the quality and efficiency of each stage of the project. Our experience and expertise in the field of engineering and infrastructure construction support us.

The construction of the Santa Maria Dam is a milestone for the region and for the world.

TAMAULIPAS 2022

JEBLA's solid, industrial and hospital waste incineration plant is the perfect solution for safe

and efficient waste management. With our state-of-the-art technology, we guarantee

proper waste disposal, protecting the environment and public health.

Our incineration plant meets the highest quality standards and complies with all environmental regulations. We use a controlled incineration process that guarantees the complete destruction of waste, thus avoiding any risk of contamination.

With JEBLA's incineration plant, companies can safely dispose of their solid, industrial and hospital waste. Our team of experts will take care of the entire process, from waste collection to final disposal.

Don't risk your employees' health or your company's reputation. Trust JEBLA and our incineration plant to safely and efficiently handle your solid, industrial and hospital waste. Contact us today for more information about our services.

Welcome to PROENSI, a pioneering engineering company in cutting-edge industrial

technology, with the most innovative solutions.

With our unwavering commitment to excellence, we have earned a reputation as a worldclass

turnkey supplier capable of transforming your vision into reality.